0769-82730118

CH

National consultation hotline

0769-82730118

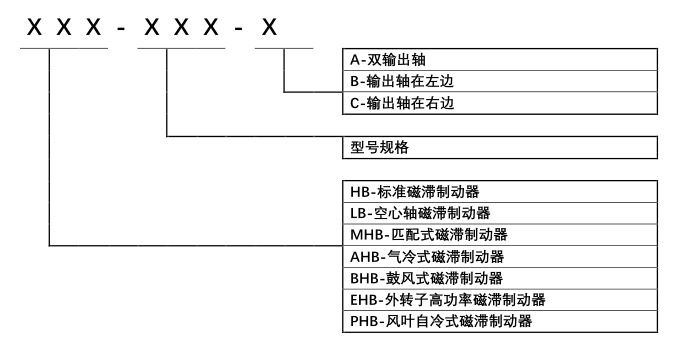

Selection reference:

|

Model |

Rated torque |

Rated current |

Voltage |

Coil resistance (At 25℃±10%) |

weight |

Rated slip power |

Moment of inertia |

Peak speed |

|

|

5 minutes |

continued |

||||||||

|

kg·cm |

mA |

VDC |

Ω |

kg |

watts |

watts |

kg·cm² |

rpm |

|

| HB-300 |

0.03 |

135 |

24 |

180 |

0.12 |

8 |

2 |

3.3×10 ¯ ⁴ |

20000 |

| HB-201 |

0.2 |

192 |

24 |

125 |

0.15 |

25 |

6 |

1.5×10 ¯ ³ |

20000 |

| HB-301 |

0.3 |

208 |

24 |

115 |

0.21 |

30 |

8 |

6.8×10¯³ |

20000 |

| HB-501 |

0.5 |

208 |

24 |

115 |

0.21 |

30 |

8 |

6.8×10¯³ |

20000 |

| HB-801 |

0.7 |

200 |

24 |

112 |

0.26 |

40 |

10 |

1.2×10¯² |

20000 |

| HB-102 |

1 |

200 |

24 |

120 |

0.39 |

55 |

15 |

4.6×10¯² |

20000 |

| HB-202 |

2 |

203 |

24 |

118 |

0.51 |

75 |

20 |

6.8×10¯² |

15000 |

| HB-302 |

3 |

390 |

24 |

62 |

0.9 |

120 |

35 |

1.8×10¯¹ |

15000 |

| HB-502 |

5 |

390 |

24 |

62 |

0.9 |

120 |

35 |

1.8×10¯¹ |

15000 |

| HB-103 |

10 |

250 |

24 |

96 |

1.8 |

320 |

80 |

1.1×10 |

15000 |

| HB-203 |

20 |

315 |

24 |

76 |

3.5 |

460 |

115 |

3.2×10 |

10000 |

| HB-303 |

30 |

750 |

24 |

32 |

5.2 |

680 |

165 |

6.8×10 |

10000 |

| HB-503 |

50 |

750 |

24 |

32 |

9.6 |

1000 |

200 |

1.3×10 |

10000 |

| HB-603 |

60 |

1500 |

24 |

16 |

11 |

1400 |

225 |

1.4×10 |

10000 |

| HB-114 |

110 |

1200 |

24 |

20 |

20.2 |

1200 |

350 |

5.6×10 |

10000 |

| HB-124 |

120 |

1200 |

24 |

20 |

21.8 |

1200 |

350 |

6.2×10 |

10000 |

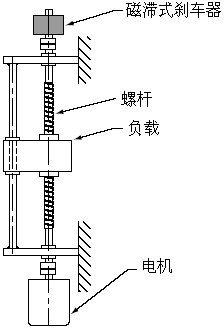

Application areas:

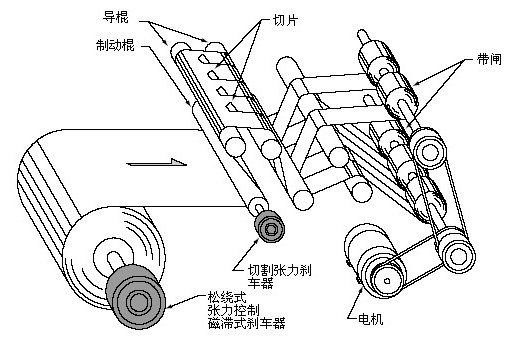

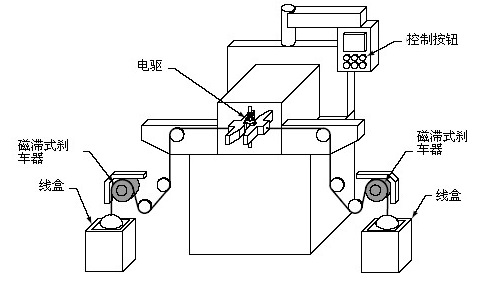

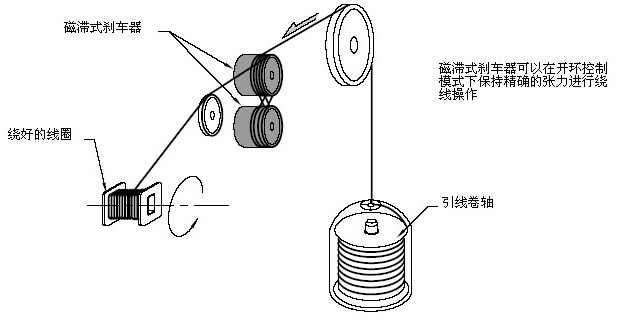

For open-loop and closed-loop control of precise torque, tension and stop positioning, such as tension control of copper wire of winding machine in motor manufacturing industry, tension control of cable transformer, textile and other industries, and precise positioning control of machine tools and intelligent automation equipment.

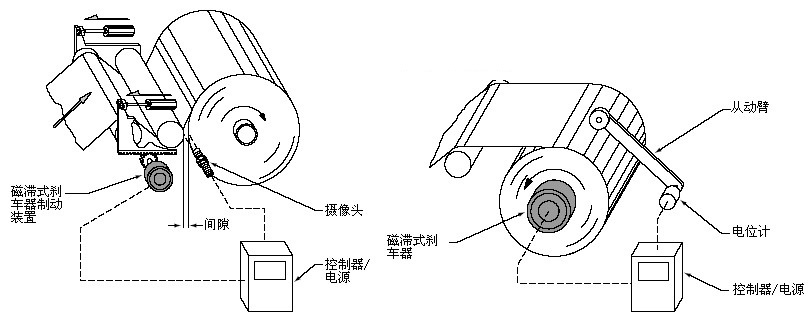

Application picture: