0769-82730118

CH

National consultation hotline

0769-82730118

Product name:High-precision motor test equipment

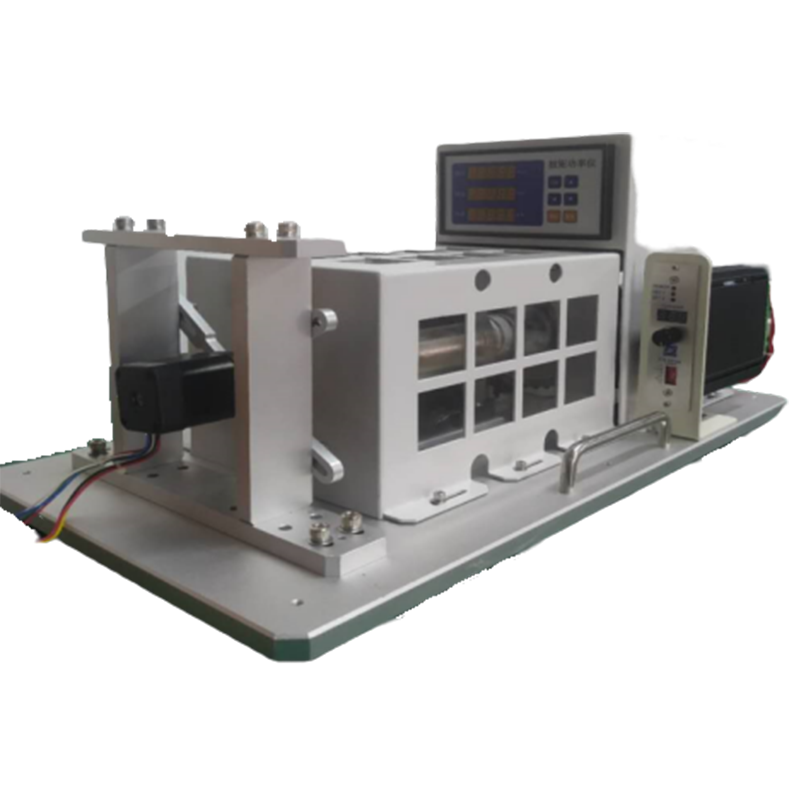

C0-MTDD-CCW-01 is a convenient; safe; high-precision motor test equipment, which is composed of the motor power (AC/DC), hysteresis brake, motor test fixture, torque speed sensor and so on. Widely used in engineering research and development, production line testing of stepping and servo motors and drives.A dynamometer customized by a well-known enterprise motor drive R&D center in Shenzhen is convenient and safe; high-precision stepping motor test system.

product description:

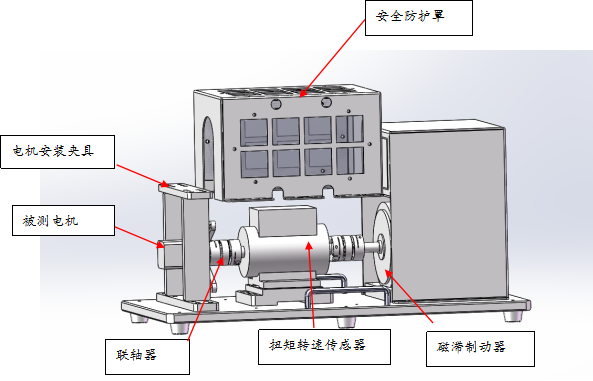

•Mechanical mechanismThe

hysteresis brake output shaft is connected to the output shaft of the torque and speed sensor through a high-precision elastic coupling, and the output shaft of the torque and speed sensor is connected to the motor under test through a high-precision elastic coupling Output shaft connection. The safety-related devices involved in the rotating part are all wrapped by metal + acrylic safety shields. Six shock mounts are installed under the test base to reduce the test error caused by the vibration during the test.

• ErgonomicsThe

operation aspect involves the convenient placement of two handles on the test floor to facilitate the movement of the device. In view of data visualization, in order to consider the need to watch the display panel during the test, the display panel is installed through an embedded structure, which is convenient for the experimenter to see at a glance. The loading operation instrument is placed on the right side of the bottom plate, and the operation is supported by the L-shaped bracket.

• work

by driving a motor drive control motor rotation speed sensor and the torque hysteresis brake, hysteresis brake load is measured on the motor and the load capacity is driven by the constant current source programmable intelligent control.

Load range and accuracy: 2A-1mA

Torque range and accuracy: 10N.m-0.1%

Speed range and accuracy: 10-10000RPM-0.1%

• Description of internal structure