0769-82730118

CH

National consultation hotline

0769-82730118

Aerospace motor online automation performance test case:

A comprehensive state-of-the-art automatic motor comprehensive performance testing device customized by a well-known state-owned aerospace motor manufacturer in Guiyang can be seamlessly connected to the entire automated production line. The system automatically determines and sends defective products to defective boxes based on test specifications, greatly improving production efficiency With quality stability.

Features:

1. Unmanned factoryization: The workstation communicates with the PLC and the server, and it is triggered by the PLC to automatically read the test configuration corresponding to the server database and start the test; after the test is completed, the test data is automatically uploaded to the server and the PLC is notified to proceed. One step.

2. Automatic switching of dynamometer: with HDC-1040 load controller and dynamometer converter, switch the dynamometer head according to the corresponding configuration of the server, without manual operation, to meet the complex needs of customer customized motor mixed line testing.

3. Load test: test the torque, speed, voltage, current, power of the motor under different loads, and

Determine whether it is qualified

4. Locked-rotation test: test the current of the motor in the locked-rotation state and the temperature at the specified locked-rotation time.

5. Scan code function: Before testing, each motor can scan its serial number by QR code.

6. Database connection function: test the data of each motor can be uploaded to the server according to the prescribed format.

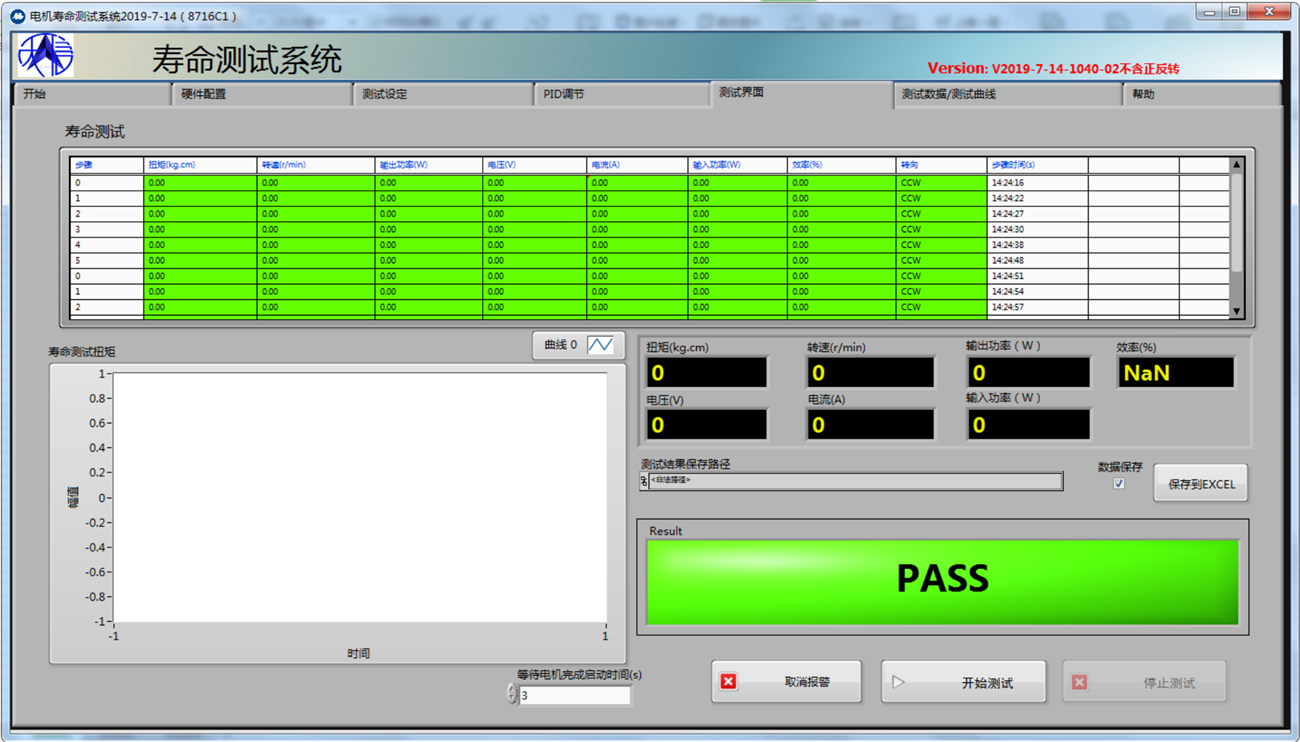

Test interface

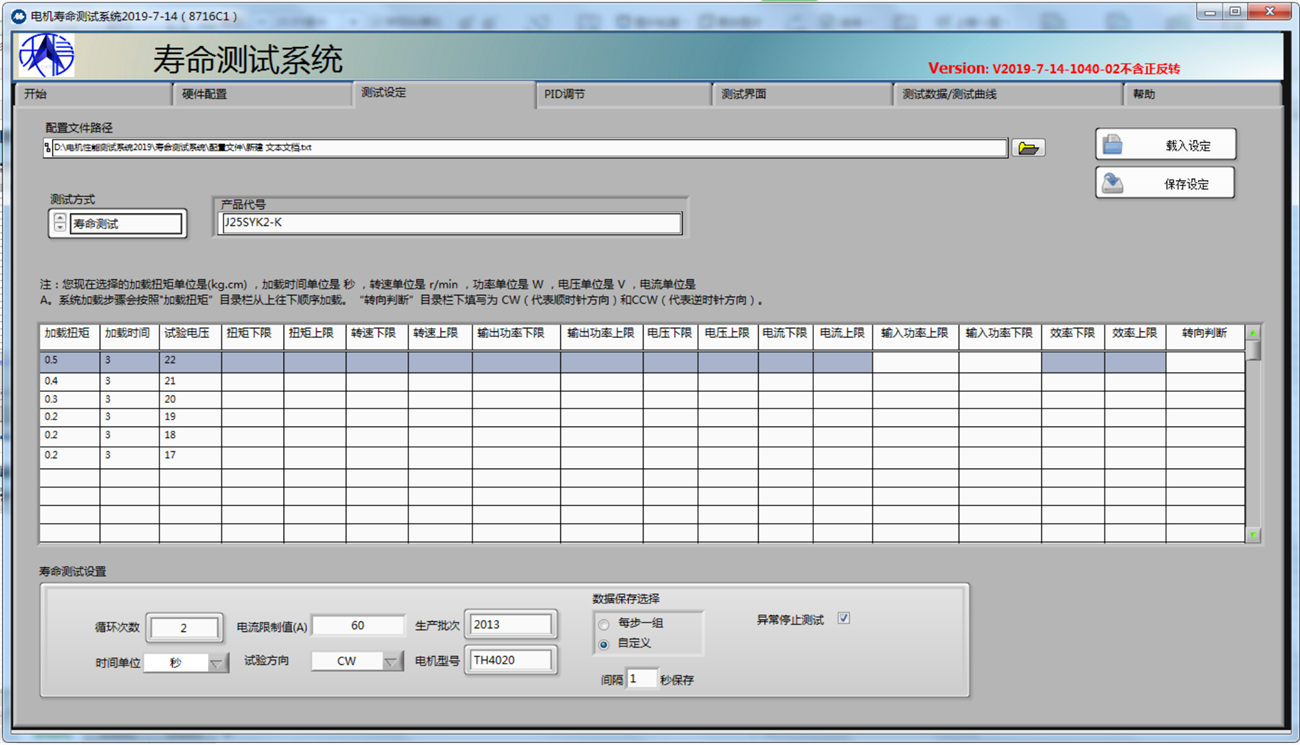

Test settings

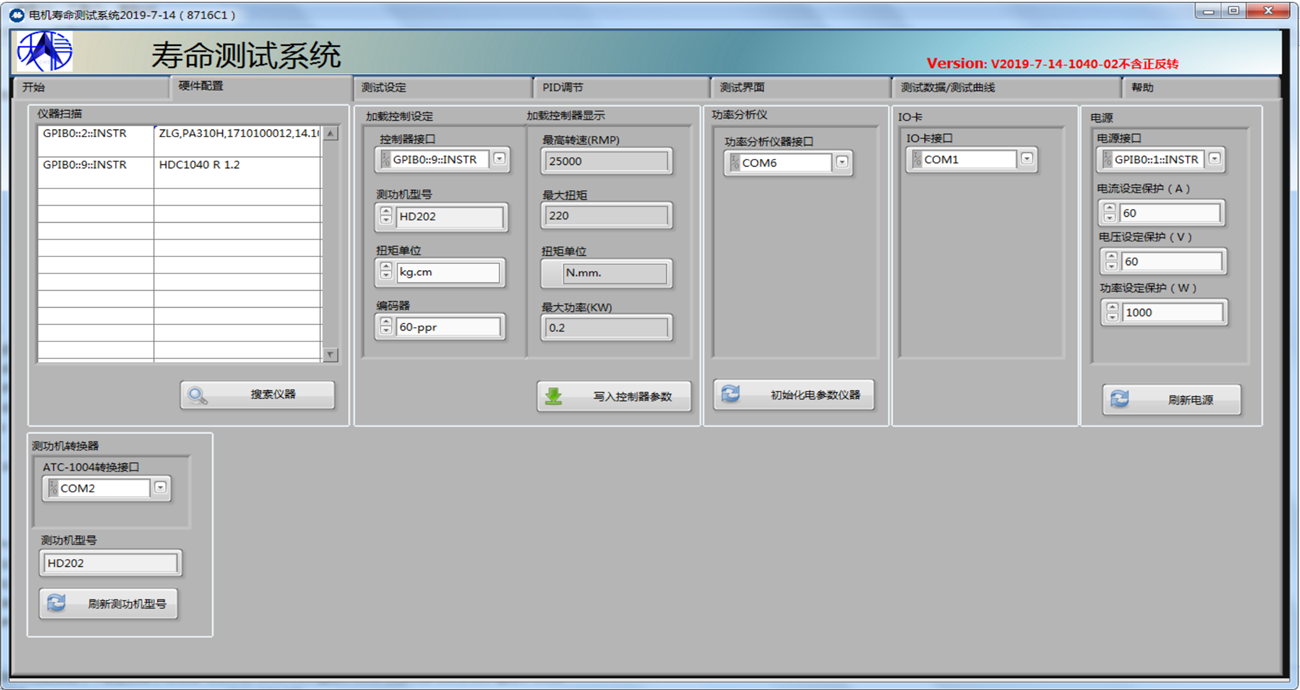

Hardware Configuration