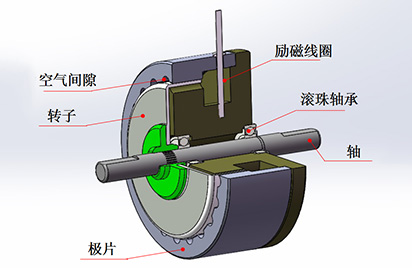

Working principle

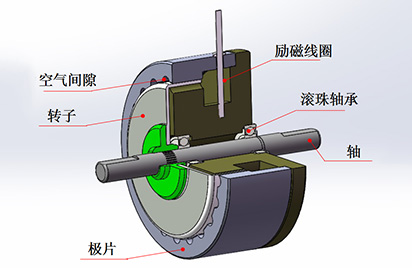

The hysteresis effect in magnetism is applied to torque control by using two basic components-mesh pole structure and special steel rotor/shaft assembly are installed together, but not in physical contact. Before the pole structure is energized, the towing cup can rotate freely on its bearings. When the magnetizing force from the excitation coil is applied to the pole structure, the air gap becomes a magnetic flux field and the rotor is magnetically confined, thereby providing braking or clutching between the pole structure and the rotor.

Working principle

The hysteresis effect in magnetism is applied to torque control by using two basic components-mesh pole structure and special steel rotor/shaft assembly are installed together, but not in physical contact. Before the pole structure is energized, the towing cup can rotate freely on its bearings. When the magnetizing force from the excitation coil is applied to the pole structure, the air gap becomes a magnetic flux field and the rotor is magnetically confined, thereby providing braking or clutching between the pole structure and the rotor.

The superior design of these hysteresis devices provides several inherent advantages over magnetic particles and friction devices. They operate under frictionless design principles with little wear. This has the following advantages: longer life expectancy, better torque repeatability, life cycle cost advantage, wide speed range, excellent environmental stability and excellent operational fluency.

In current-controlled hysteresis brakes, torque adjustment and control is provided by the excitation coil. This allows full control of the torque by adjusting the DC current of the excitation coil. Adjustable from a minimum value (bearing resistance) to a maximum value of 10-20% above the rated torque. These brakes use the same working principle as our permanent magnet hysteresis brakes, but the magnetic field is replaced with a magnetic field coil, which provides the precise magnetic field strength required for the rated torque.

In current-controlled hysteresis brakes, torque adjustment and control is provided by the excitation coil. This allows full control of the torque by adjusting the DC current of the excitation coil. Adjustable from a minimum value (bearing resistance) to a maximum value of 10-20% above the rated torque. These brakes use the same working principle as our permanent magnet hysteresis brakes, but the magnetic field is replaced with a magnetic field coil, which provides the precise magnetic field strength required for the rated torque.

Residual magnetic force:

When the exciting current suddenly changes to less than 50% of the initial value and does not rotate the rotor, the residual magnetic force will be generated, and the torque will fluctuate during operation. Effective methods to avoid torque fluctuations are:

• Manually turn the stator and rotor separately while gradually reducing the excitation current

• Gradually reduce the excitation current

before the equipment is shut down • Disconnect the low excitation current before the equipment is shut down (between the stator and the rotor) Relative speed is above 100 rpm)

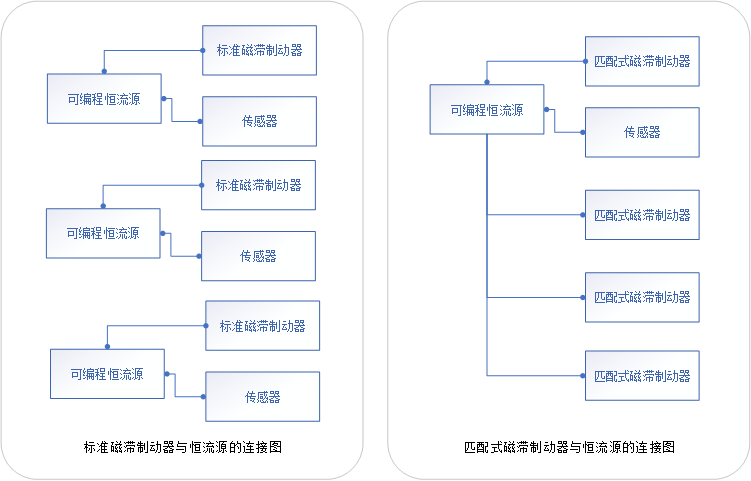

Comparison between standard hysteresis brake and MHB series matched hysteresis brake:

Note: All standard hysteresis brakes can be designed as matched hysteresis brakes. The specifications of these matched hysteresis brakes are the same as the standard hysteresis brakes. For example, MHB-503 has the same specifications as HB-503.

We'd like to hear your opinion

Whether you want to know us or have any suggestions, we will be glad to hear from you.

Working principle

Working principle