0769-82730118

CH

National consultation hotline

0769-82730118

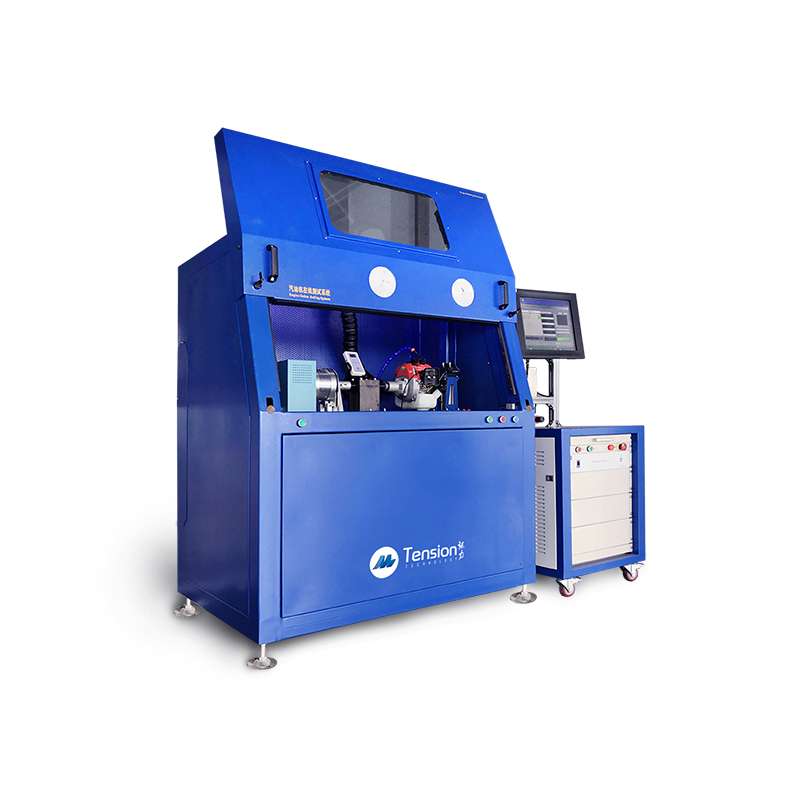

Product name:Gasoline engine performance debugging system

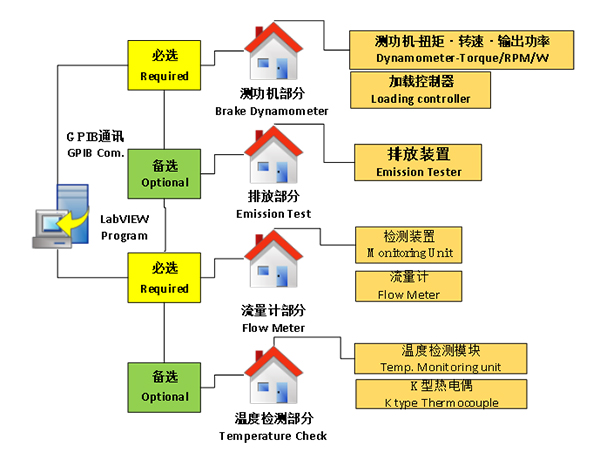

CMT-1040GHS The system is based on dynamometer, loading controller, flow meter, emission analyzer, and other peripheral test equipment. The online debugging of the engine is controlled by LabVIEW software. The test uses electric start, no manual start.

Features:

•Using dynamometer to load, realize adjustable load controllable management

• Use high-speed cylinder to realize electric start instead of manual pull start, and automatically control throttle pull

• The shell is soundproofed, and the noise can be controlled below 75db according to the requirements of the national standard. It can be directly placed on the U-shaped installation line to achieve lean production and improve production efficiency.

• The test bench adopts shock absorption design to ensure that the maximum vibration does not affect the normal operation of the engine

• An exhaust emission system is set in the test box to ensure that the internal environment does not affect the normal operation of the engine

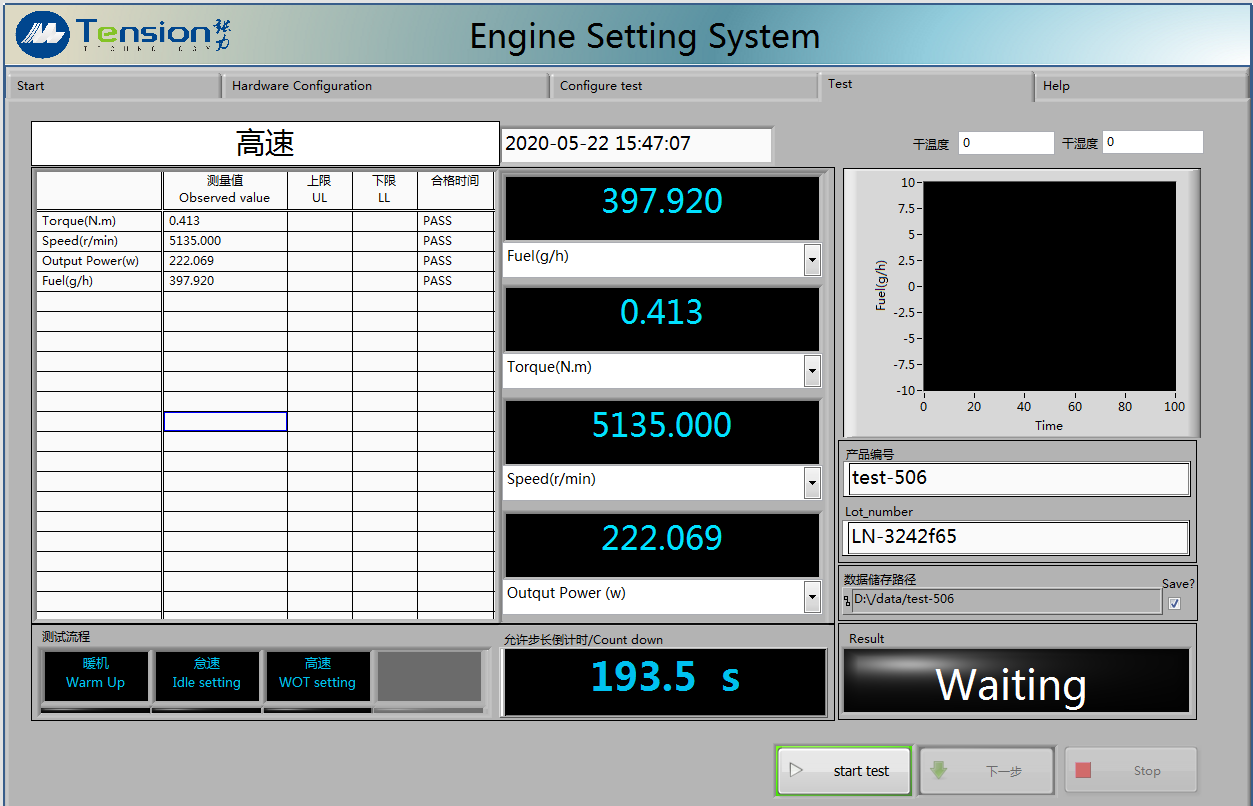

• Visualized management can be achieved, real-time online display of the tested parameters, the system can automatically determine the 8. ratio based on the actual measured values and standard values, and automatically prompt the current test stage and status (by lamp management)

Gasoline engine test interface

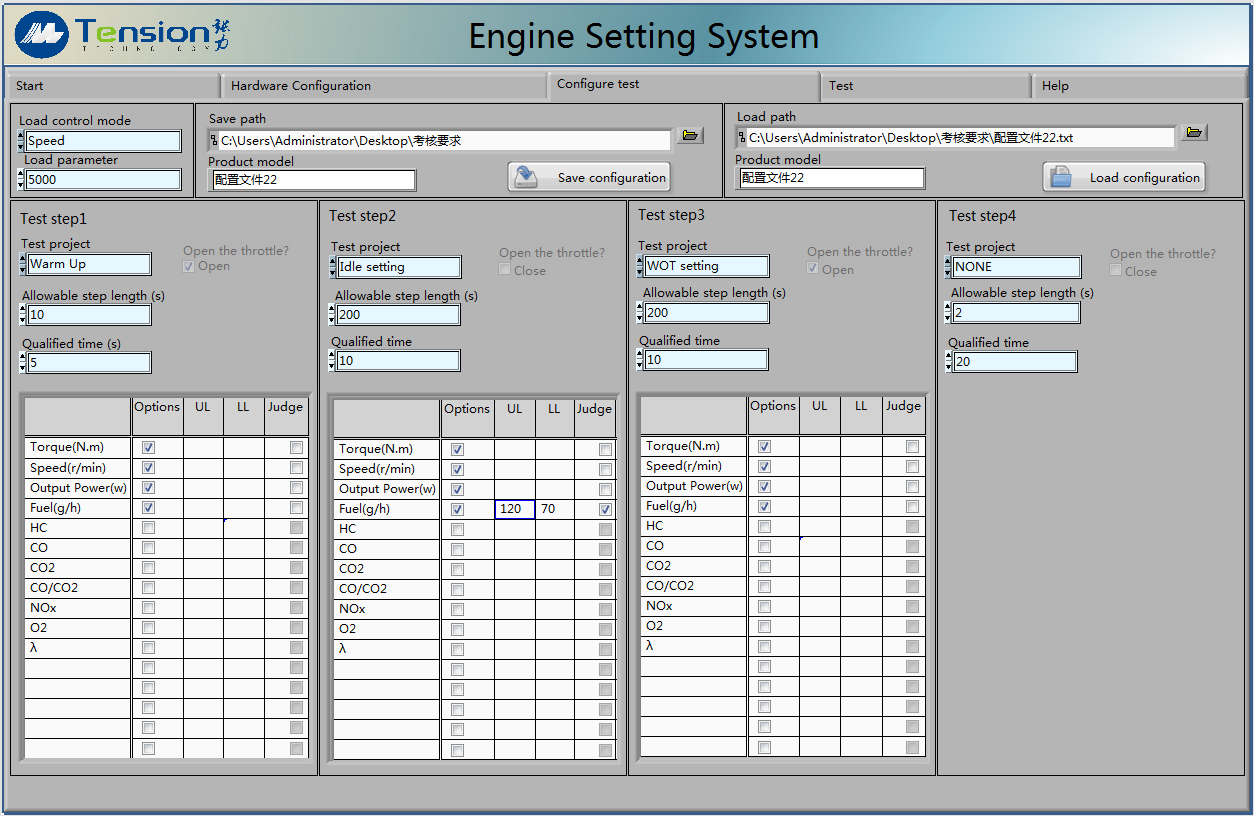

Gasoline engine setting interface

• Automatic storage and management of test data, and can be connected to the database to achieve data security management, and perform data analysis according to requirements

• The piece is a Chinese operation interface, which is divided into an engineering interface and an operator interface, and permissions can be set according to customer requirements

• Engineers can set and save test programs according to different test requirements of the product. The operator only needs to call the corresponding test program according to the product code each time the test is performed. The system also supports QR code scanning to automatically identify and call the corresponding test program to achieve Foolproof function and perfect traceable management

Application areas:

3-10KW small gasoline engine performance debugging and safety test