0769-82730118

CH

National consultation hotline

0769-82730118

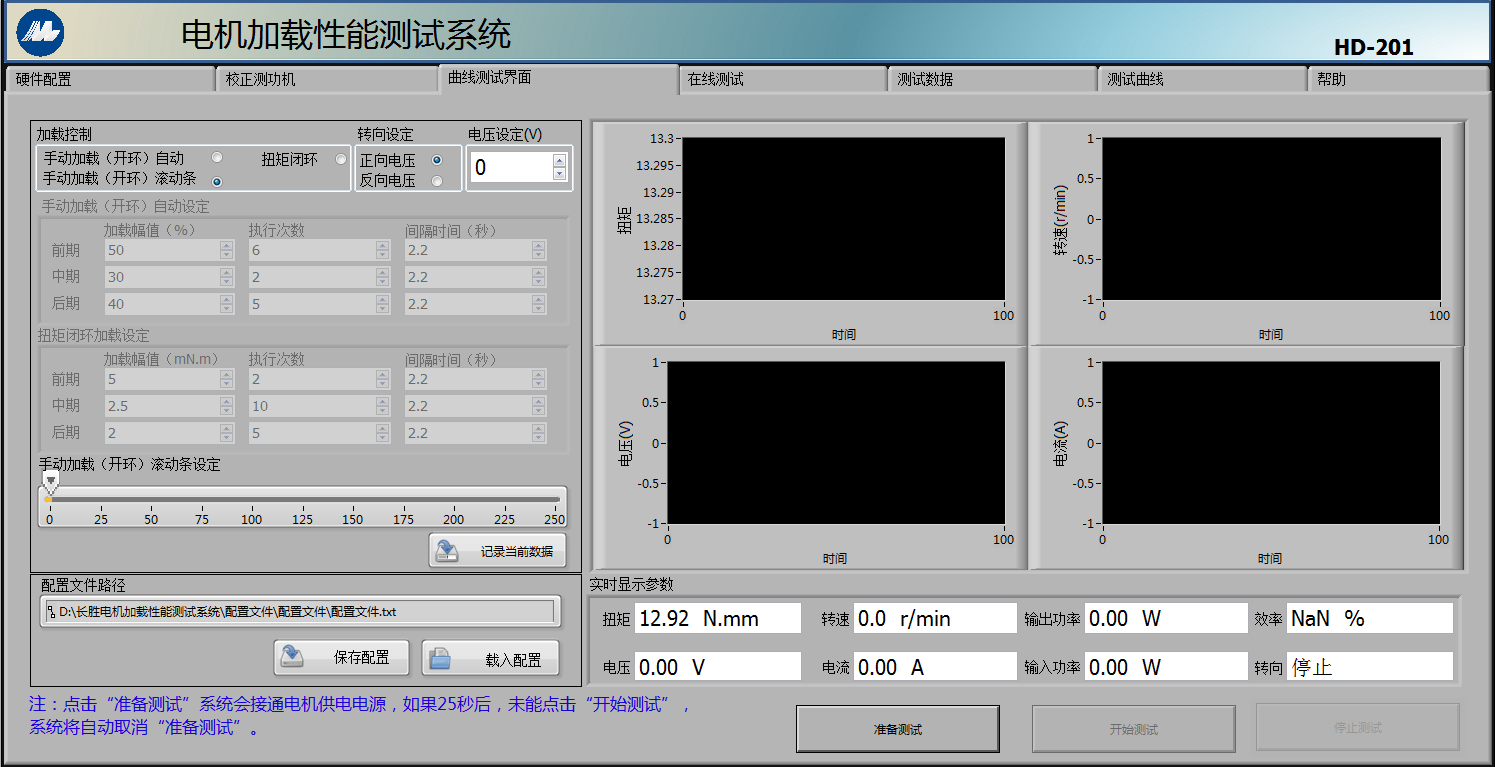

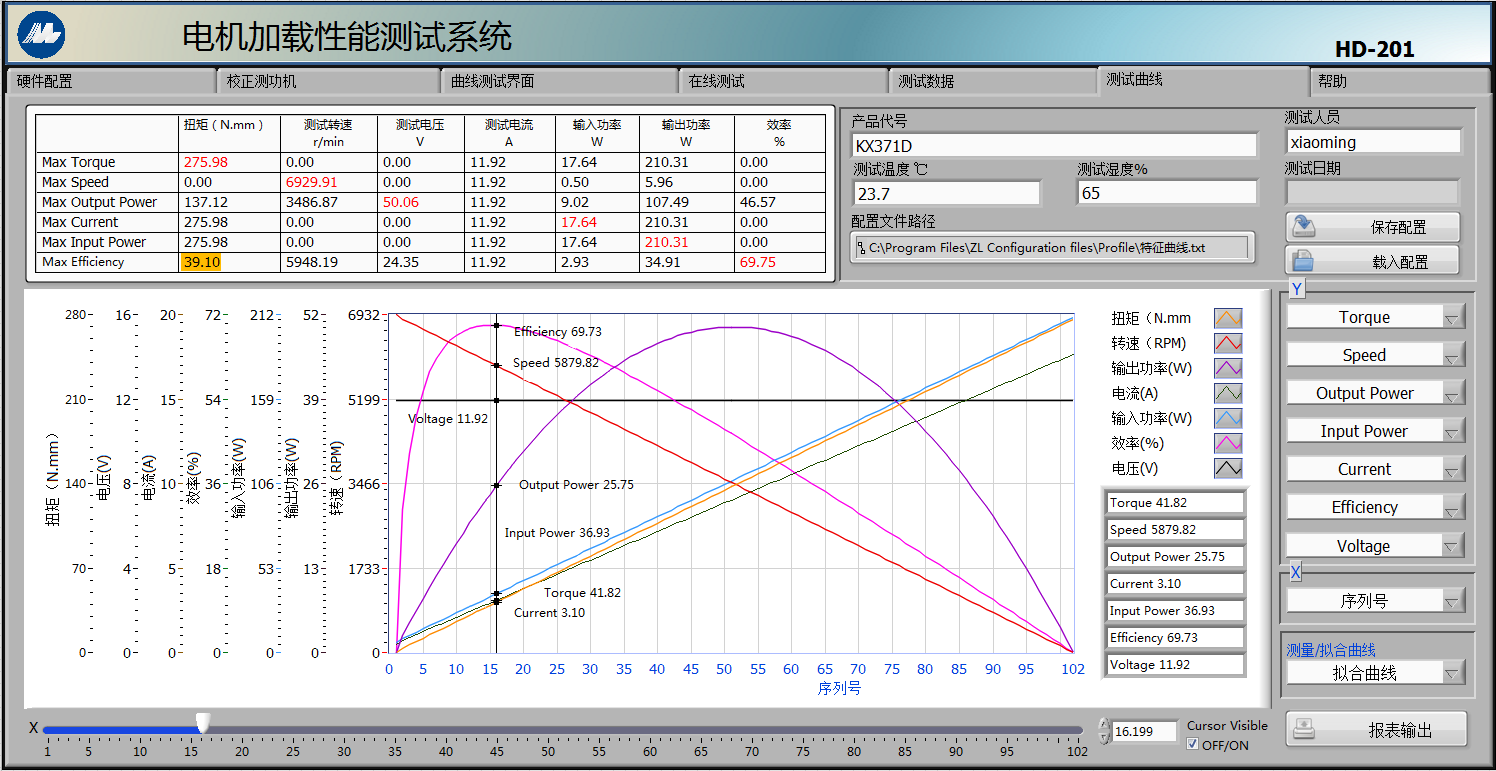

UAV motor performance test case:

Motor comprehensive performance testing equipment for a well-known UAV company in Shenzhen. There are two types of brushless UAV motors: one is the inner rotor brushless motor, and the other is the outer rotor brushless motor.

1. Internal rotor brushless motor: refers to the motor shaft will rotate, the coil is in the motor shell, and the magnet is in the shaft. The advantages of the inner rotor brushless motor: Generally speaking, because of its small diameter, it is more conducive to the high speed torque.

2. Outer rotor brushless motor; refers to the motor casing will rotate, the coil is on the axis, and the magnet is on the casing. Brushless inner rotor motor and brushless outer rotor

The advantages of the motor:

The advantages of the outer rotor brushless motor: it has better heat dissipation and a larger diameter, which is more conducive to the exertion of low-speed torque.

Increase the tension measurement and control of this type of motor by applying a load to the motor through the hysteresis dynamometer to simulate the actual operating conditions of the motor to check the performance parameters of the motor at different speeds and different torques, and draw the efficiency cloud map for analysis during motor design

Features:

1. The speed of the motor can be controlled through communication

2. Temperature rise test: add load to the motor under the rated voltage or run the motor for a long time with no load to test the temperature of the motor coil through the K-type thermocouple.

3. Life test: The load is applied to the motor through the dynamometer. The motor runs at rated voltage for not less than 200 hours.

4. The test software is written in LABVIEW, with the characteristic test and graph drawing function, which can calculate and display multiple parameters (torque, speed, output power, voltage, current, input power, efficiency, steering, etc.)

5. Test accuracy: torque: 0.2%; speed: 0.1%; voltage/current: 0.1%.